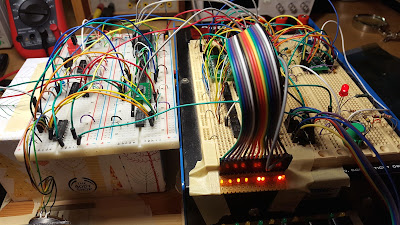

Wiring it up

The drum machine project is getting near the end. It still needs to be put mechanically together and do the wiring. Although I have designed the system, it still came a bit as a surprise how much wiring there actually is. I found myself drawing wiring diagrams page after page. Wiring of this complexity level cannot be done without proper diagrams, at least I cannot plan and solder at the same time. The parts that need to be interconnected: 8 circuit boards upper front panel (part of the chassis) 15 pots, part of them tandem 6 push switches a 7-position rotary switch lower front panel (part of the housing) 16 sequencer buttons, with leds 1 start/stop button, with led connectors at the back line out external sync speaker One of my many hand-drawn diagrams, the trigger wiring. I won’t put them all here, the re are too many of them , and part of them are not easy to understand for anyone else. Here is the chassis built up, sound control pots and push swit